English

- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

Leading China's Magnesium Hydroxide Manufacturing for Over 15 Years

We offer comprehensive solutions across multiple industries, supported by our unique mineral and synthetic product centers.

Contact Us Now

WHAT WE CAN PROVIDE

Products

-

Hexagonal Magnesium Hydroxide

HP series is a kind of halogen free environmentally friendly flame retardant Have two types: non-coated and coated with special additives especially designed for HFFR, EVA and other high requirement polyolefin products.View All

-

Ultrafine Nano Magnesium Hydroxide

Ultrafine Nano Magnesium Hydroxide – P1 Series is a halogen-free flame retardant for PE, PP, EVA, XLPE, and engineering plastics. With ≥95% Mg(OH)₂, it delivers high LOI, good thermal stability, and cost savings. Available in uncoated, silane-coated, and stearic acid-coated grades.View All

-

Precipitated Magnesium Hydroxide

MgCl2+2NH3•H2O=Mg(OH)2↓+2NH4Cl Coated by KMT patent formula, easy dispersing in PP, PE, EVA, POE, EPDM, XLPE, PA, ABS compound.View All

-

ATO (Antimony Trioxide) Replacement

AM3V is an antimony-free flame retardant based on Al-Mg co-precipitated LDH, designed for FRLS PVC. It offers high LOI (≥30), low smoke, cost savings, and excellent dispersion—ideal for replacing ATO+ATH or ATO+MDH systems.View All

-

Hydromagnesite

Nature own fire retardant. Hydromagnesite Chemical formula: [3MgCO3 · Mg(OH)2 · 3H2O] This unique natural minerals is also known as HMH. It is a proven fire retardant filler in a wide range of polymers and rubbers such as EVA, POE, polyethylene (PE), polyvinyl chloride (PVC), ethylene-propylene diene monomer (EPDM) and Nitrile Rubber (NBR).View All

-

Brucite

The production of natural Brucite is started in the year 2008. We offer high purity and high whiteness Brucite powder. B series Brucite is widely used in PVC cable, HFFR cable compound, flame retardant panel, aluminum composite panel, flue gas desulfurization, wastewater treatment, magnesium fertilizer, etc.View All

-

Aluminum Hydroxide

High purity Aluminum Hydroxide can be used as halogen free flame retardant for plastic and rubber industry due to its well distributed granularity, good stability, non toxic and non-polluting.View All

WE ARE MANUFACTURER

About KMT

KMT Industrial (HK) Ltd, was founded in 2008. KMT is specializing in researching, producing and selling Hexagonal Magnesium Hydroxide, Precipitated magnesium hydroxide, Hydromagnesite, Brucite powder, Aluminum Hydroxide, and other flame retardant products.

We have one R&D center, two plants, dozens of patents, and the plants are ISO9001, ISO14001, ISO45001 certificated, Dun & Bradstreet code 554405380.

All the products comply with RoHS requirements and have EU REACH registration.

1

R&D

2

Factories

30+

Export countries

OUR ADVANTAGES

Why Choose Us

-

01R&D

01R&D R&D

R&D Our R&D team drives innovation by refining products and developing new solutions to meet market demands.

Our R&D team drives innovation by refining products and developing new solutions to meet market demands. -

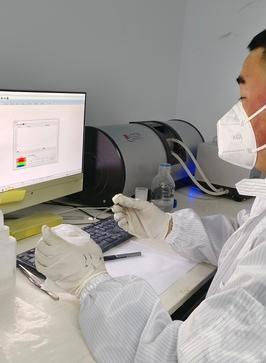

02QC&QA

02QC&QA QC&QA

QC&QA Our QC&QA processes ensure high-quality products through rigorous inspections and advanced testing.

Our QC&QA processes ensure high-quality products through rigorous inspections and advanced testing. -

03Global Warehouse

03Global Warehouse Global Warehouse

Global Warehouse Our global warehouse network enables efficient service and quick order fulfillment for our clients.

Our global warehouse network enables efficient service and quick order fulfillment for our clients. -

04Exporting

04Exporting Exporting

Exporting Our export expertise allows us to deliver products efficiently and competitively in international markets.

Our export expertise allows us to deliver products efficiently and competitively in international markets.

WHAT CAN YOU GET

Technical Support

FIELDS OF APPLICATION

Application

-

1

Wire and Cable

View All KMT products, featuring key ingredients like Magnesium Hydroxide, Hydromagnesite, and Aluminum Hydroxide, serve as effective flame retardants and smoke suppressants in wires and cables, enhancing safety in critical applications.

KMT products, featuring key ingredients like Magnesium Hydroxide, Hydromagnesite, and Aluminum Hydroxide, serve as effective flame retardants and smoke suppressants in wires and cables, enhancing safety in critical applications.

-

2

Building Materials

View All KMT products serve as flame retardants and fillers in diverse building applications, utilizing key components like Brucite Powder, Precipitated Magnesium Hydroxide, and Aluminum Hydroxide to enhance fire safety and durability while meeting stringent building standards.

KMT products serve as flame retardants and fillers in diverse building applications, utilizing key components like Brucite Powder, Precipitated Magnesium Hydroxide, and Aluminum Hydroxide to enhance fire safety and durability while meeting stringent building standards.

-

3

Electronic and Electrical Applications

View All KMT products, featuring Precipitated Magnesium Hydroxide and Aluminum Hydroxide, enhance flame resistance and performance in electrical cables, circuit boards, and electronic housings, ensuring safety in components susceptible to overheating.

KMT products, featuring Precipitated Magnesium Hydroxide and Aluminum Hydroxide, enhance flame resistance and performance in electrical cables, circuit boards, and electronic housings, ensuring safety in components susceptible to overheating.

-

4

Other Industrial Applications

View All KMT products, including Precipitated Magnesium Hydroxide, are versatile and enhance performance in various industries such as modified sealants, magnesium fertilizer, water treatment, and flue gas desulfurization.

KMT products, including Precipitated Magnesium Hydroxide, are versatile and enhance performance in various industries such as modified sealants, magnesium fertilizer, water treatment, and flue gas desulfurization.

Let's Work on Your Next Project.

Get a Quote Right Now

Get a Quote Right Now

Get Started

EVENTS

Latest Events

-

Jan 30, 2026

What Is the Optimal MDH Loading to Reach UL94 V-0?

Master MDH loading strategies for UL94 V-0 certification. Get polymer-specific loading percentages, formulation tips, and synergistic additive recommendations from KMT Industrial's technical experts. -

Jan 22, 2026

AM3V: The Next-Generation Flame Retardant Replacing ATO in PVC Compounds

Discover AM3V, KMT Industrial’s innovative flame retardant replacing ATO in PVC compounds. Achieve high LOI (≥30), low smoke density, and 1/15th the cost. -

Jan 19, 2026

How Magnesium Hydroxide Affects Polymer Rheology and Processing

Discover how magnesium hydroxide (MDH) affects polymer rheology and processing. Learn expert solutions for optimizing extrusion, injection molding, and compounding of HFFR flame retardant compounds. Technical guide for polymer engineers and manufacturers.

Contact Us Now

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products

Copyright © 2024 KMT Industrial (HK)Ltd. All Rights Reserved.

info@kmtindustrial.com

+86-931-7666997

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

What can we help?