- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

Flame Retardant Magnesium Hydroxide for Cable and Wire Industry

Table of Contents

1. Introduction to Flame Retardant Magnesium Hydroxide in the Cable and Wire Industry

2. What is Magnesium Hydroxide (MDH) and Why is it Used?

3. Types and Grades of Magnesium Hydroxide Used in Flame Retardancy

4. How Does Magnesium Hydroxide Act as a Flame Retardant?

5. Applications of Flame Retardant Magnesium Hydroxide in the Cable and Wire Industry

6. Why KMT Industry’s Magnesium Hydroxide is Ideal for Cable and Wire Manufacturing

7. How to Choose the Right Magnesium Hydroxide for Cable Manufacturing

8. Global Trends in Flame Retardant Materials for Cable and Wire Production

9. Advantages of Using Magnesium Hydroxide Over Other Flame Retardants

10. Conclusion and Recommendations

12. Frequently Asked Questions (FAQs)

1. Introduction to Flame Retardant Magnesium Hydroxide in the Cable and Wire Industry

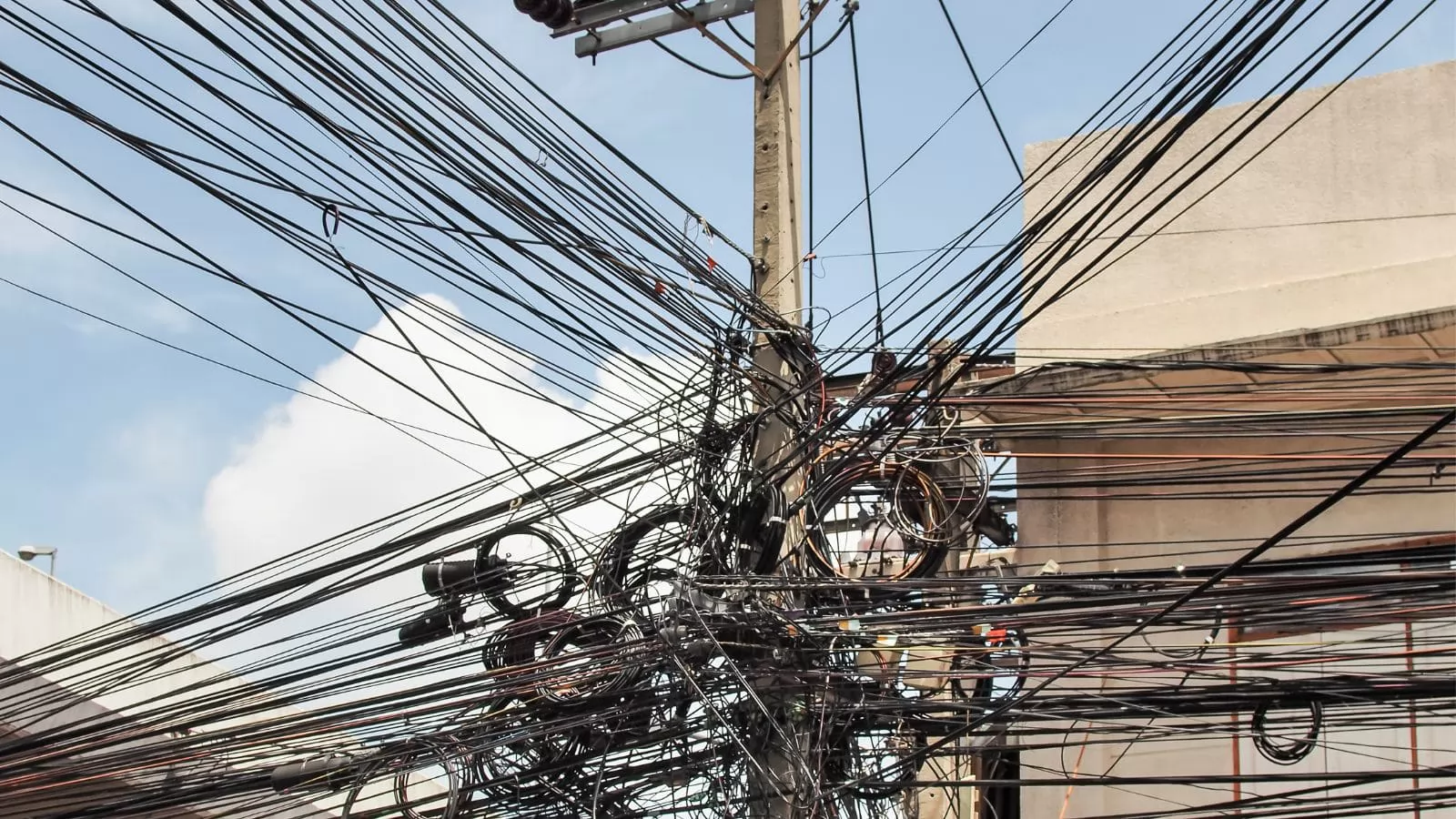

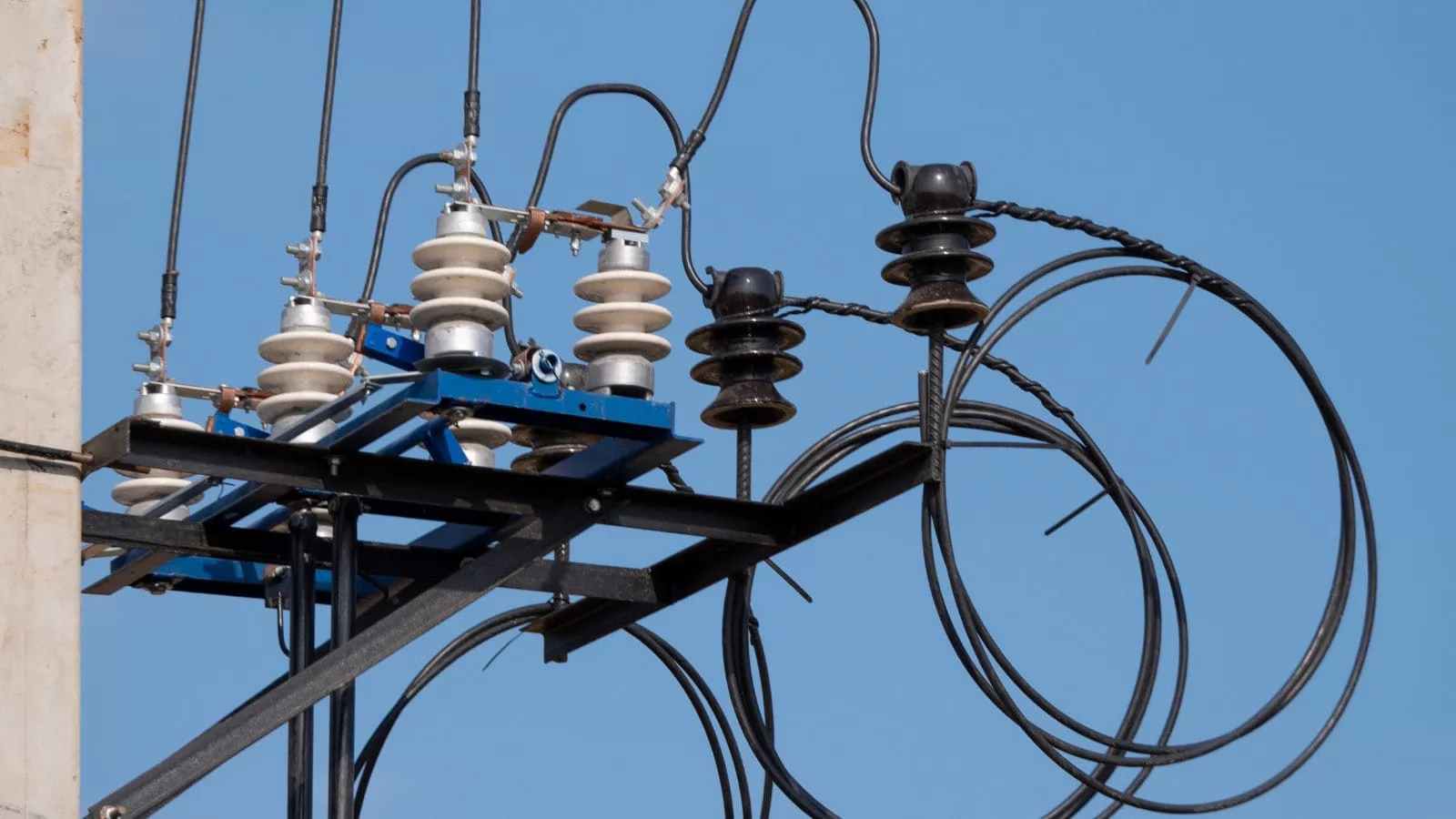

In the cable and wire industry, flame retardants are essential for ensuring the safety and durability of electrical and communication cables. Flame retardant magnesium hydroxide (MDH) has become one of the most preferred additives for this purpose. As the demand for safer and more environmentally friendly materials increases, manufacturers are turning to magnesium hydroxide for its exceptional flame resistance properties.

Flame retardant magnesium hydroxide is used extensively in the production of cables, wires, and other electrical components, where it serves as an effective and sustainable solution to reduce the risk of fire hazards. This guide explores the different types, grades, and applications of magnesium hydroxide in the cable industry, with a particular focus on the offerings from KMT Industry.

2. What is Magnesium Hydroxide (MDH) and Why is it Used?

Magnesium hydroxide (MDH) is an inorganic compound often used in flame retardant applications. Known for its ability to decompose endothermically (absorbing heat and releasing water vapor), it effectively suppresses flames and reduces the spread of fire. This makes it an excellent choice for cable and wire insulation.

KMT Industry specializes in the production of various grades of magnesium hydroxide, including hexagonal magnesium hydroxide and precipitated magnesium hydroxide, which offer exceptional flame retardancy, high purity, and low impurity content. The product is particularly useful in industries that require high-quality flame retardants without compromising on environmental sustainability.

3. Types and Grades of Magnesium Hydroxide Used in Flame Retardancy

Flame retardant magnesium hydroxide is categorized into different types and grades based on production methods, particle size, surface coating, and crystal structure. These factors influence the material's performance in various applications, especially in cable and wire manufacturing.

3.1 By Production Method

· Synthetic Magnesium Hydroxide: Synthesized through chemical reactions, it is highly pure and white, offering excellent flame retardancy. KMT Industry’s XK series, for example, uses the Nh2·H2O reaction method, resulting in high purity and excellent processing performance.

· Hydrothermal Method Magnesium Hydroxide: A more complex preparation process involving water at high temperatures, resulting in a specific crystalline form.

· Ore-Method Magnesium Hydroxide (Brucite Powder): Derived directly from brucite ore, this method involves mining, crushing, grinding, and sometimes modifying the powder for enhanced flame retardancy.

KMT Industry employs a range of methods to produce magnesium hydroxide that meets the highest industry standards.

3.2 By Surface Coating Modification

Surface modification plays a key role in enhancing the properties of magnesium hydroxide, especially in terms of dispersibility, compatibility, and flame resistance.

· Uncoated Grade: The raw powder, without any surface treatment, suitable for general flame retardant applications.

· Stearic Acid Surface Coating: Used to improve flowability and compatibility in plastic and cable formulations.

· Silane Surface Coating: Enhances the bonding properties of magnesium hydroxide with polymers, ensuring better dispersion in the final product.

· Composite Additives Coating: A blend of surface treatments that improve the overall performance of the magnesium hydroxide.

3.3 By Particle Size

The particle size of magnesium hydroxide influences its performance in flame retardancy. Smaller particles have a larger surface area, improving their ability to suppress flames.

· 325 Mesh: D50 > 10 microns

· 1250 Mesh: D50 6-7 microns

· 2500 Mesh: D50 5-6 microns

· 5000 Mesh: D50 2.6-3 microns

· 10000 Mesh: D50 1-2 microns

Each size has specific applications depending on the type of cable or wire being produced.

3.4 By Crystal Structure

Magnesium hydroxide crystals come in various forms, each with different properties:

· Hexagonal Flake Magnesium Hydroxide: Best-performing grade, offering high flame resistance with regular hexagonal shapes.

· Fibrous Magnesium Hydroxide: Stronger mechanical properties but lower flexibility.

· Flaky Non-Hexagonal Magnesium Hydroxide: Offers a larger surface area but lower performance than the hexagonal form.

4. How Does Magnesium Hydroxide Act as a Flame Retardant?

Magnesium hydroxide acts as a flame retardant by releasing water vapor when exposed to heat. This endothermic reaction cools the surrounding area, slowing the spread of fire. Additionally, it creates a protective layer that prevents further combustion.

In cable manufacturing, magnesium hydroxide is incorporated into insulation materials to provide fire resistance without the toxic fumes associated with traditional flame retardants. KMT Industry’s magnesium hydroxide products offer high thermal stability and excellent flame resistance, making them a top choice for cable manufacturers worldwide.

5. Applications of Flame Retardant Magnesium Hydroxide in the Cable and Wire Industry

Flame retardant magnesium hydroxide is primarily used in the cable and wire industry for the following applications:

· Power Cables: To prevent fires in electrical systems, especially in areas with high fire risk.

· Communication Cables: Providing additional safety for data and telecom cables that are widely used in commercial and residential buildings.

· Automotive Cables: Used in automotive wiring harnesses to ensure the safety of the electrical system in case of overheating or fire.

· Industrial Cables: Flame retardant properties are essential in industrial environments, especially for cables used in high-temperature conditions.

KMT Industry’s range of magnesium hydroxide products is ideal for all these applications, providing consistent quality and reliable performance.

6. Why KMT Industry’s Magnesium Hydroxide is Ideal for Cable and Wire Manufacturing

KMT Industry is a leader in the production of high-quality magnesium hydroxide products, including hexagonal and precipitated grades, that cater specifically to the needs of the cable and wire industry.

· High Purity & Quality: KMT Industry’s products are known for their purity and low impurity content, ensuring superior flame retardancy.

· Sustainability: KMT Industry focuses on environmentally friendly production methods, providing eco-friendly flame retardant solutions.

· Customization: KMT Industry offers a wide range of particle sizes and surface coatings, allowing manufacturers to choose the best product for their specific needs.

By choosing KMT Industry, you are investing in a reliable and sustainable flame retardant solution that meets the highest safety standards in the cable industry.

7. How to Choose the Right Magnesium Hydroxide for Cable Manufacturing

Selecting the right grade of magnesium hydroxide depends on several factors, including:

· Cable Type: Different cables require different levels of flame retardancy.

· Application Environment: The temperature and environmental conditions in which the cable will be used.

· Desired Performance: Factors like mechanical strength, ease of processing, and dispersion need to be considered.

KMT Industry’s wide range of magnesium hydroxide products allows for tailored solutions that meet specific manufacturing needs.

8. Global Trends in Flame Retardant Materials for Cable and Wire Production

The global market for flame retardants in the cable industry is shifting towards more sustainable and non-toxic solutions. There is a growing preference for magnesium hydroxide over halogenated flame retardants due to its environmental benefits and superior safety performance.

9. Advantages of Using Magnesium Hydroxide Over Other Flame Retardants

Compared to traditional flame retardants, magnesium hydroxide offers numerous benefits:

· Non-Toxic: It doesn’t release toxic gases when exposed to heat, unlike halogenated flame retardants.

· Environmental Benefits: Magnesium hydroxide is an eco-friendly alternative that meets increasing environmental regulations.

· Higher Performance: It offers superior thermal stability and flame resistance, making it suitable for demanding applications.

10. Conclusion and Recommendations

Flame retardant magnesium hydroxide is an essential material in the cable and wire industry, providing a safe, effective, and environmentally friendly solution for flame retardancy. With its excellent properties and performance, KMT Industry’s magnesium hydroxide products stand out as a top choice for cable manufacturers worldwide.

11. Related Blogs

· 9 Things Need to Be Considered When Choosing Flame Retardant

· Brucite B3SL and B3V Contrast Experiment

· Basic Knowledge of Mixed Silicone Rubber

12. Frequently Asked Questions (FAQs)

Q: What is the best type of magnesium hydroxide for cable manufacturing?

A: It depends on the specific requirements of the cable, such as temperature, mechanical strength, and fire resistance. KMT Industry offers a range of options, including hexagonal and fiber-based magnesium hydroxide.

Q: Is magnesium hydroxide eco-friendly?

A: Yes, magnesium hydroxide is a sustainable and non-toxic flame retardant, making it an eco-friendly choice for various industries.

Your Name*

Your Email*

-

2025-Mar-26MDH PM5SN vs. M5SM: Top Flame Retardant Showdown in EVA FormulasWhich magnesium hydroxide wins in EVA? Compare PM5SN vs. M5SM for flame retardancy, strength, and processing—expert results revealed!

-

2025-Mar-25Fix LSZH Cable Issues: Rough Surfaces, Slow Speeds SolvedRough LSZH cables or slow production? Get expert fixes from 10+ years in the industry. Improve HFFR efficiency today!

-

2025-Mar-17Top 10 Magnesium Hydroxide Manufacturers in 2025The top ten magnesium hydroxide manufacturers and suppliers leading the global market in 2025, the evaluation report is provided by the strongest ai model Grok3.

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products