English

- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

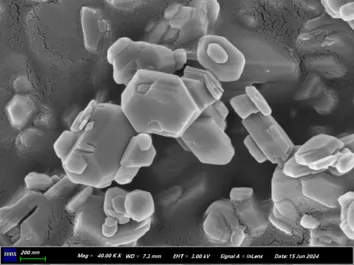

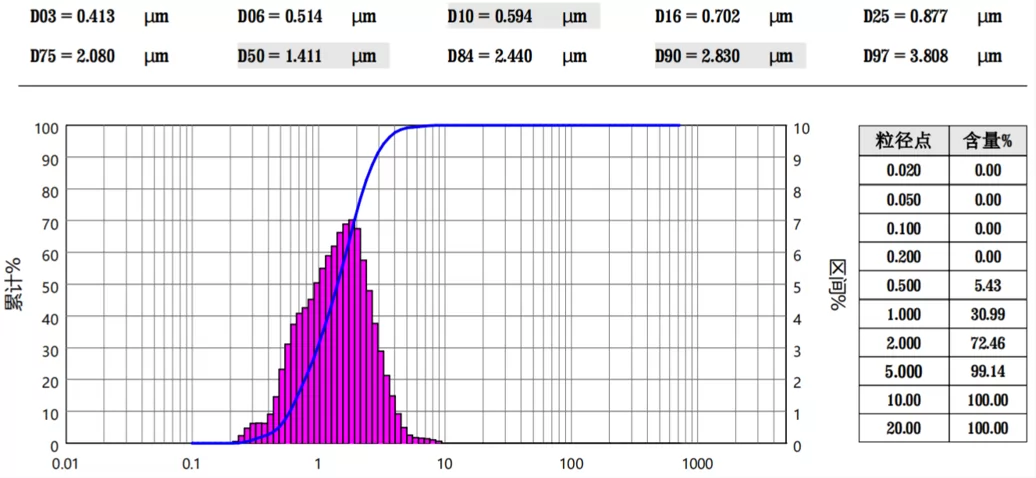

Hexagonal Magnesium Hydroxide Wholesale

Focuses on the research and development of precipitated magnesium hydroxide. Annual production capacity exceeds 30,000 tons.

Products

Need More Help?

Give us a e-mail and chat with our team today!

Get Started

Hexagonal Magnesium Hydroxide

Synthetic magnesium hydroxide, halogen free flame retardant for PE, PP, POE, EPDM, EVA, XLPE, PVC, TPU, PA and ABS based compound.

HP series products comply with RoHS requirements and have REAC- KMT Hexagon plate structure provides good fluidity and dispersion.

- Could achieve high elongation at break.

- Good charing formation performance.

- BET controlled

- Easy dispersing

- Lower compounding torque

- Higher compound MFI

Contact Us Now

Description

Reviews

HP Series

Introduction

Halogen free flame retardant for PE, PP, POE, EPDM, EVA, XLPE, PVC, TPU, PA and ABS based compound.

HP series products comply with RoHS requirements and have REACH certification.

Advantages

KMT Hexagon plate structure provides good fluidity and dispersion.

Could achieve high elongation at break.

Good charing formation performance.

BET controlled. Easy dispersing.

Lower compounding torque.

Higher compound MFI.

Processing temperature less than 300°C

Packing: 25kg bag or big bag.

Share your thoughts with us today!

Showing

Yamada -

JP

5/5 stars

Jan 31.2025

Their R&D co-developed a 300°C-stable HP7N/ATH blend for our automotive PP. Passed 1,200hrs thermal cycling without torque fluctuations.

Sato -

DE

5/5 stars

Jan 03.2025

Their HP7's <0.002% Fe₂O₃ eliminated discoloration in medical-grade tubing. REACH compliance simplified EU exports.

Lagos -

NG

5/5 stars

Nov 05.2024

KMT's Turkish warehouse stocked P1S silane-grade MDH within 72hrs during port strikes. Maintained 100% production uptime for our African cable clients.

Müller -

DE

5/5 stars

Sep 10.2024

Validated HP7's ≤0.002% Fe₂O₃ purity for medical-grade PVC tubing. Zero ionic contamination in 6M accelerated aging tests.

Petrov -

RS

5/5 stars

Aug 20.2024

Switched to P1SA's stearic coating for HFFR PE pipes - 18% higher MFI vs. traditional MDH. Cut energy costs by 2.8¢/kg during Balkan infrastructure rollout.

Zhang -

CN

5/5 stars

Jul 15.2024

KMT's HP7N with D50=1.6μm particle distribution eliminated our compounding filter clogs. Achieved 98% UL94 V-0 consistency across 12 extrusion lines.

Chen -

CN

5/5 stars

Mar 12.2024

KMT's HP7N with patent coating cut our PVC cable torque by 18% while maintaining UL94 V-0. Passed 48hr smoke density tests first attempt.

Alvarez -

US

5/5 stars

Dec 25.2023

Switched to P1SA's stearic acid coating for truck tarp compounds - 12% faster extrusion rates vs. traditional MDH. 0 scorching at 285°C throughput.

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products

Copyright © 2024 KMT Industrial (HK)Ltd. All Rights Reserved.

info@kmtindustrial.com

+86-931-7666997

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

What can we help?