English

- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

High-purity Magnesium Hydroxide Wholesale

Focuses on the research and development of precipitated magnesium hydroxide. Annual production capacity exceeds 30,000 tons.

Products

Need More Help?

Give us a e-mail and chat with our team today!

Get Started

Precipitated Magnesium Hydroxide

Precipitated superfine magnesium hydroxide coated by KMT patent formula, can easy dispersing in PP, PE, EVA, POE, EPDM, XLPE, PA, ABS compound.

- High purity, high whiteness, low moisture content, high bulk density, easy flow, anti-bridge and agglomeration-resistant, easily used in auto-loading and feeding system, low compounding torque, no white spot, good surface quality and no shark skin.

- Gives good mechanical properties, good flame retardant and smoke absorb properties.

- Coating: KMT patent.

- Processing temperature less than 300°C.

- Packing: 25kg bags or big bag.

Contact Us Now

Description

Reviews

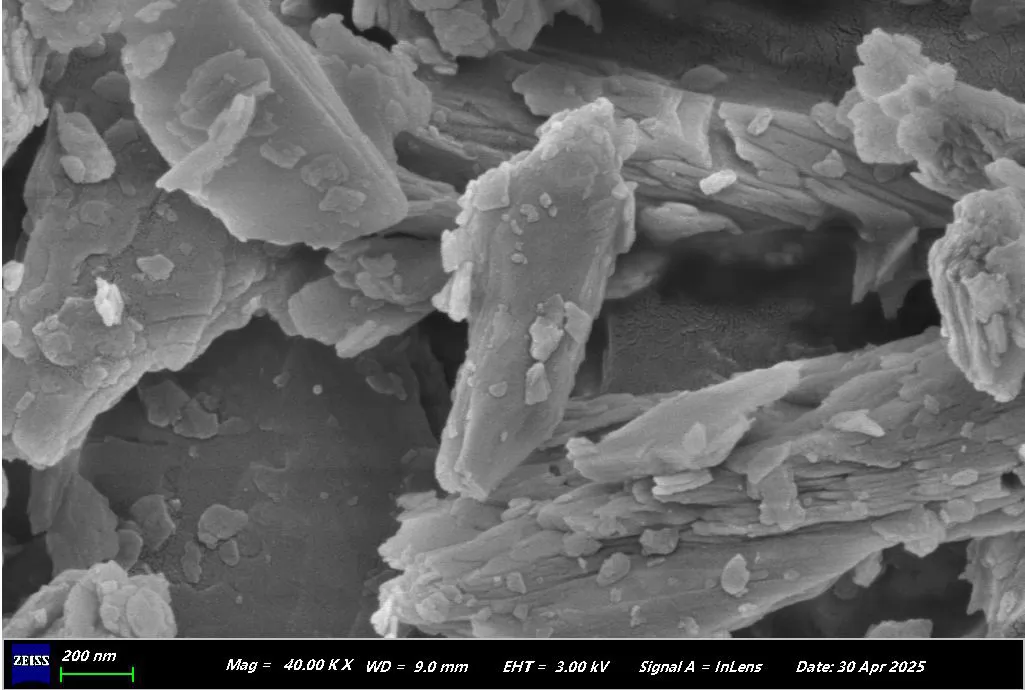

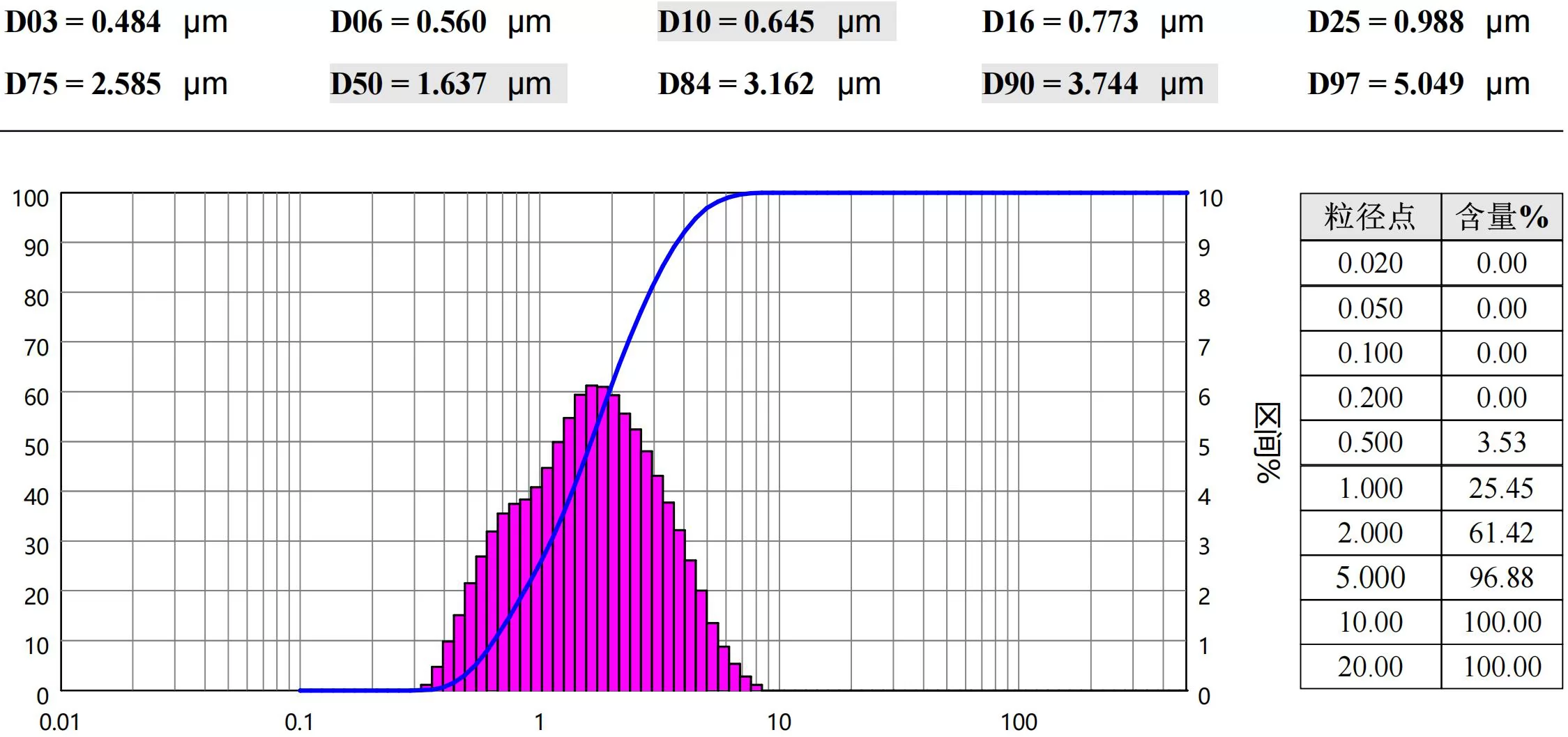

PM5S

PM5S is a silane coated super fine precipitated MDH with flake type structure and very competitive price.

What is the advantages compare to brucite

99.5% purity, 100% whiteness

PM5S offers higher purity and superior whiteness,

making it more suitable for LSZH compounds consistent quality and color uniformity.

Superfine

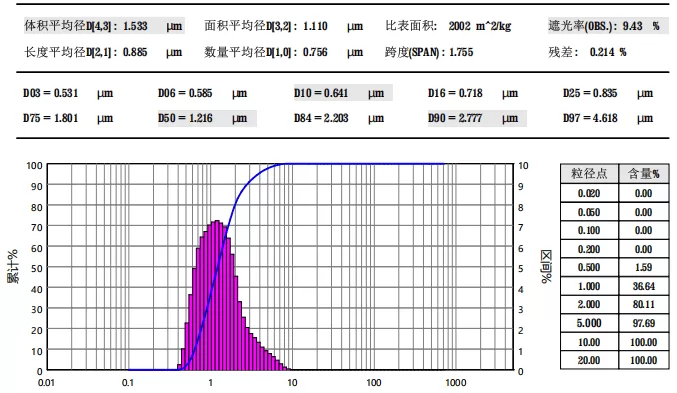

PM5S D50 is 1.6um and most brucite powder D50 is over 3um

Finer particles reducing stress concentrations

and enhancing tensile strength, modulus, impact resistance and elongation at break.

What is the advantages compare to ATH?

1: Better char-forming

Divalent metal ions promote polymer aromatization, enhances graphitic char yield,

but trivalent metal ion is not.

It means MgO can promote the carbonization of polymer, but Al2O3 is not.

So MDH makes FR compound easy pass UL burning test compare to ATH.

2: Better smoke absorbing

Divalent metal ions promote polymer aromatization, enhances graphitic char yield,

converts volatiles to stable char, but trivalent metal ion is not.

It means MgO can reduce the smoke more than Al2O3 during polymer burning.

What is smoke?

Smoke is a colloidal suspension of solid and liquid particulates in a gas (usually air),

resulting from the thermal decomposition of materials under oxygen-deficient conditions

Applications

Cable & Wire Compounds – EVA/POE jackets with V0 performance

Flame Retardant Foams – EVA or POE-based safety foams

Footwear Midsoles – Flexible EVA blends with improved fire resistance

Sheets, Films & Profiles – Smooth finish, non-blooming surfaces

PA66 + PM5S → V0-grade connectors with low smoke

ABS + PM5S → Appliance housings meeting flame/safety codes

PBT + PM5S → Auto electronics with anti-drip and heat resistance

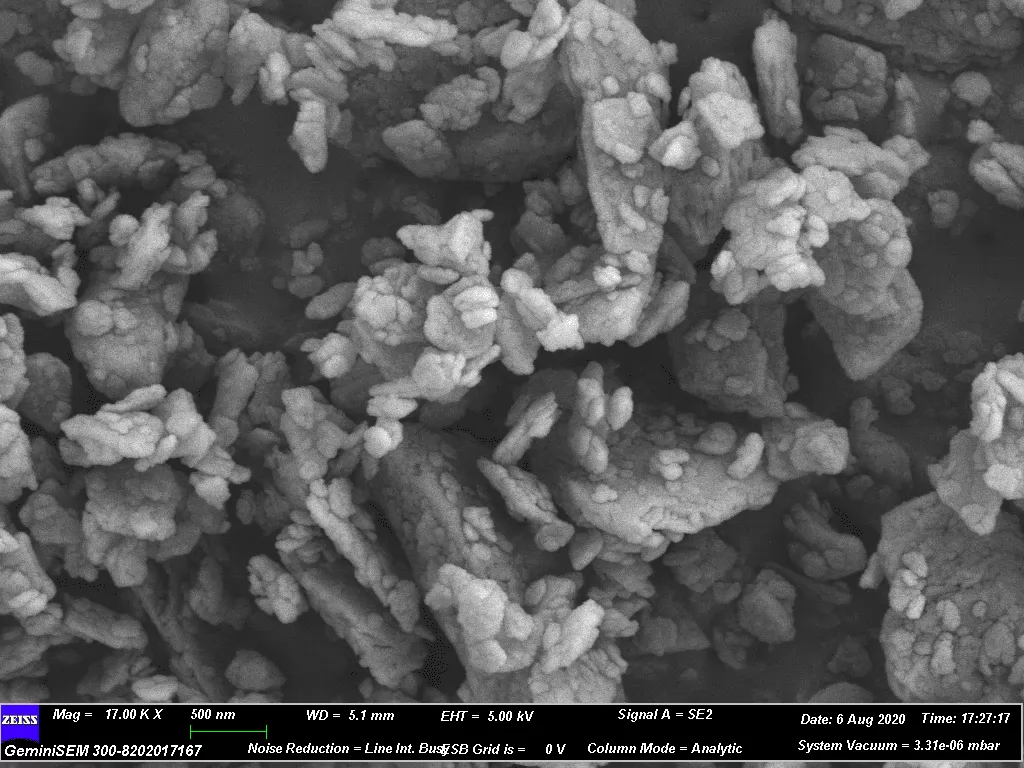

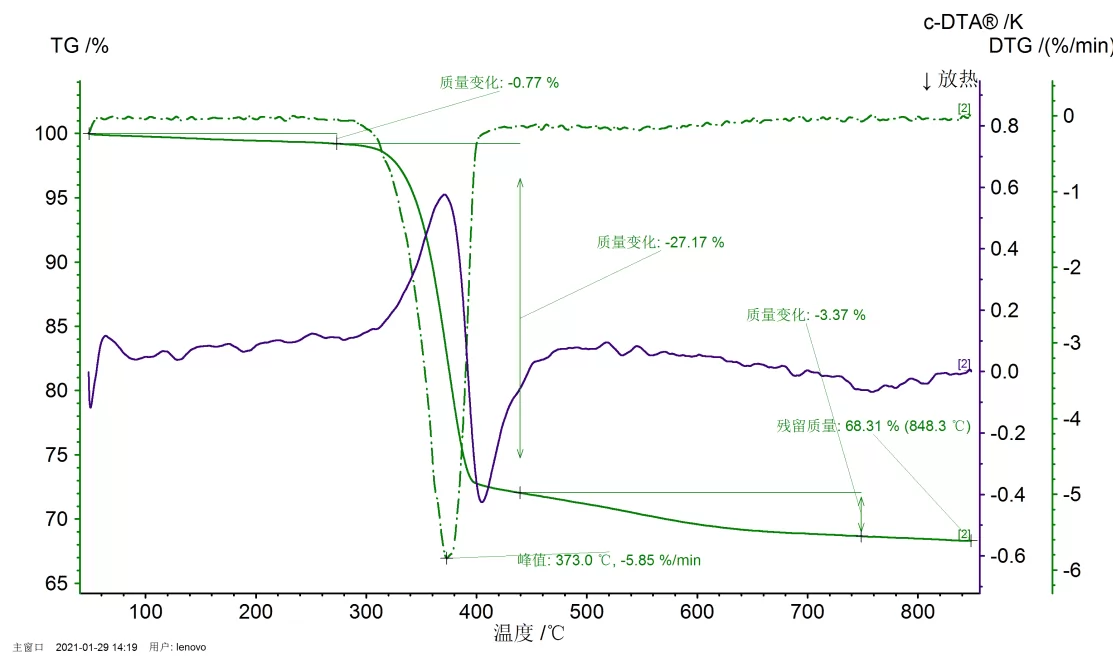

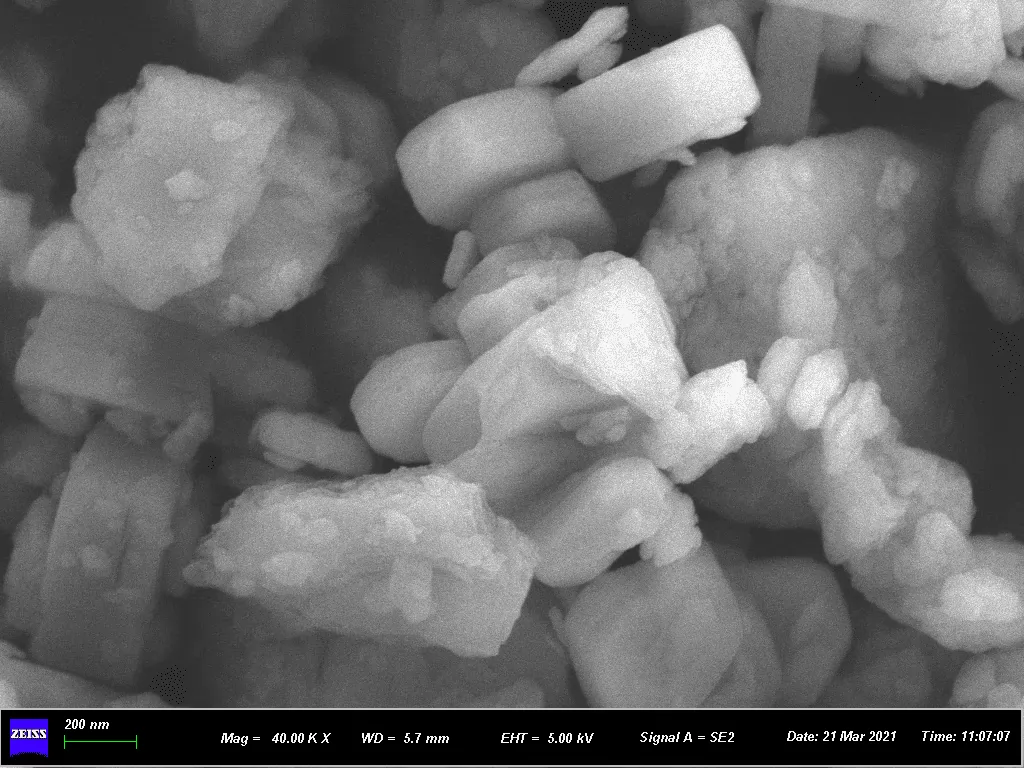

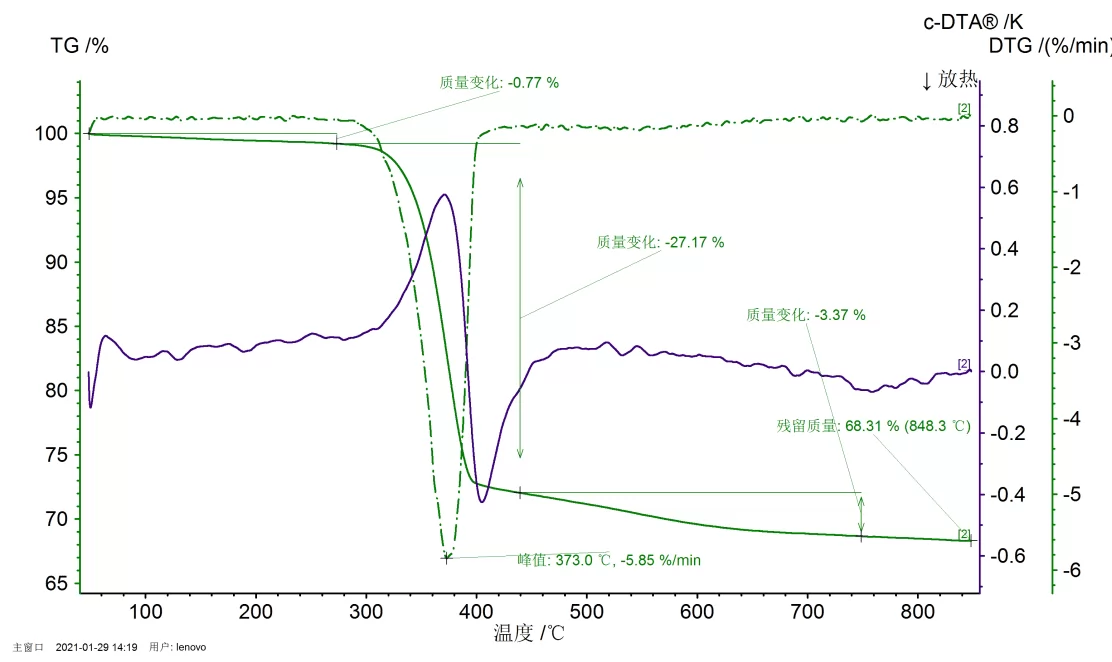

Below are SEM, PSD of PM5S

PM Series

Introduction

MgCl2+2NH3•H2O=Mg(OH)2↓+2NH4Cl

Magnesium hydroxide product are widely used as a flame retardant in the rubber and plastics industries.

Advantages

High purity, high whiteness, low moisture content, high bulk density, gives good mechanical properties, good flame retardant and smoke absorb properties.

A good replacement of hexagonal plate type magnesium hydroxide in some formulas, cost saving solution for normal HFFR compound.

High purity and BET value, also suitable as a reaction raw material for Magnesium derivatives (such as magnesium stearate).

Coating: No coating.

Processing temperature less than 300°C.

Packing: 25kg bag or big bag.

PM Series “SN” coated

Introduction

MgCl2+2NH3•H2O=Mg(OH)2↓+2NH4Cl

Coated by KMT patent formula, easy dispersing in PP, PE, EVA, POE, EPDM, XLPE, PA, ABS compound.

Advantages

High purity, high whiteness, low moisture content, high bulk density, easy flow, anti-bridge and agglomeration-resistant, easily used in auto-loading and feeding system, low compounding torque, no white spot, good surface quality and no shark skin.

Gives good mechanical properties, good flame retardant and smoke absorb properties.

Good replacement of hexagonal plate type magnesium hydroxide in some formulas, cost saving solution for normal HFFR compound.

Processing temperature less than 300°C.

Packing: 25kg bags or big bag.

Share your thoughts with us today!

Showing

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products

Copyright © 2024 KMT Industrial (HK)Ltd. All Rights Reserved.

info@kmtindustrial.com

+86-931-7666997

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

What can we help?